Why the Tesla Battery Upgrade Signals the End of New Cars

Buying a brand-new vehicle has always felt inevitable; after a few years the odometer climbs, the warranty expires, and the next model year looks shinier. Tesla just shattered that mindset with its headline-grabbing Tesla battery upgrade. For only $5,000, owners of Model 3 or Model Y vehicles built after 2021 can swap their aging lithium-ion pack for a cutting-edge aluminum ion battery that delivers a jaw-dropping 1,000 mile range and a 5 minute EV charging experience. The concept doesn’t merely improve performance—it alters the economics of ownership. Instead of budgeting tens of thousands for a replacement car, drivers can extend the useful life of the one sitting in their driveway for a fraction of the cost. Traditional automakers have historically relied on planned obsolescence to keep assembly lines humming, but Tesla’s strategy flips the script by turning every vehicle into a long-term platform that gains value over time. The primary keyword—Tesla battery upgrade—captures this pivot perfectly, because it is no longer about selling more sheet metal; it’s about selling continuous capability. In this article we’ll unpack the science behind the aluminum ion battery, explore how the retrofit slots effortlessly into existing chassis, and examine why the aftermarket will never look the same. Along the way you’ll discover related insights (see our previous analysis of Supercharger V4 rollout) that show how the charging network, software subscriptions, and future vehicle-to-grid programs knit together into one powerful ecosystem.

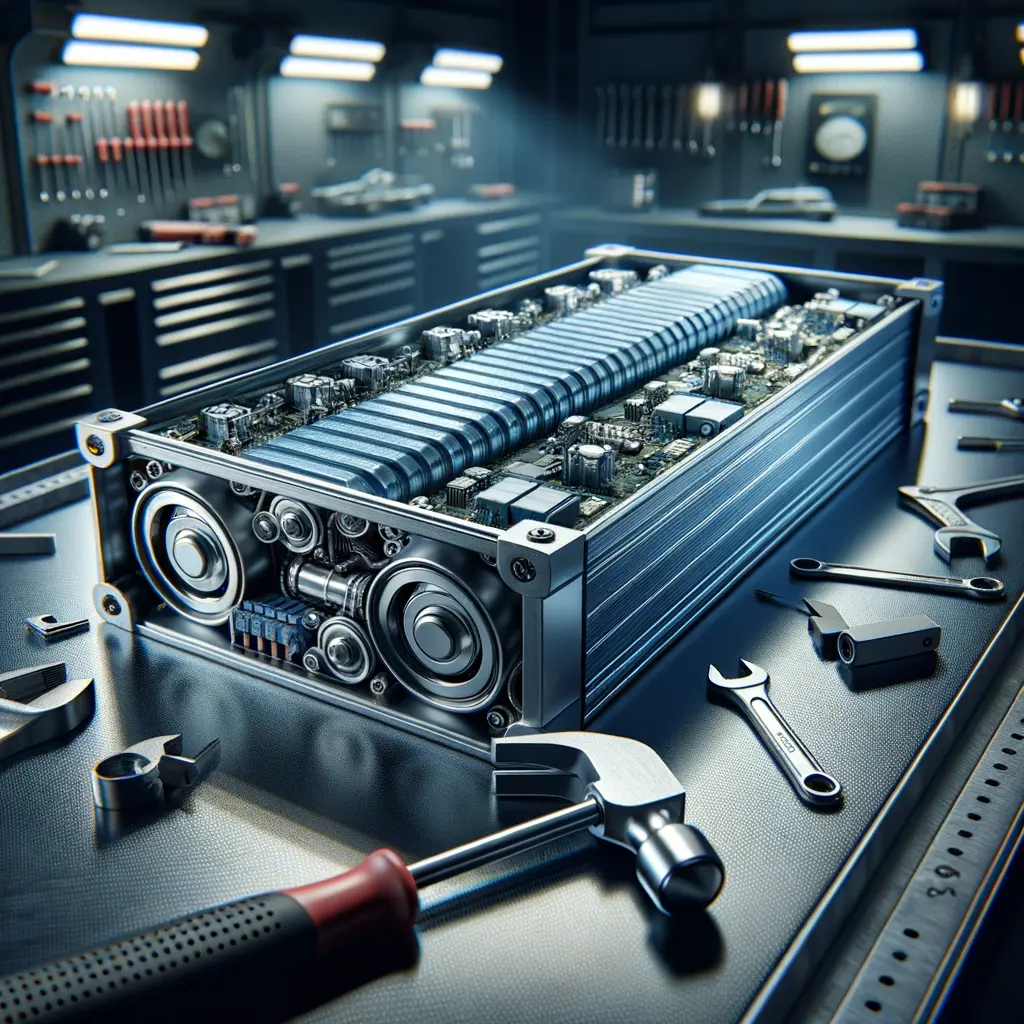

Inside the $5K Aluminum Ion Battery: Science and Specs

Aluminum is the most abundant metal in Earth’s crust, and Tesla’s research team leveraged that ubiquity to create an aluminum ion battery that pairs affordable raw materials with blistering performance. The pack’s core chemistry uses graphene-based electrolytes to accelerate ion movement, enabling ultra-rapid electron exchange and minimal thermal buildup. Each cell operates at roughly 20 volts—far higher than the 3.8 volts typical of lithium ion—so fewer cells are needed to achieve the same overall voltage, slashing internal resistance and heat generation. The result: a battery capable of delivering a true 1,000 mile range while tolerating six-times-faster charge rates. To keep temperatures below 45 °C during a 5 minute EV charging session, engineers embedded micro-channels that circulate coolant beneath every module, complemented by integrated heat pipes bonded to a thick aluminum plate that functions as a giant heat sink. Weight was another hurdle. At about 1,250 lb, the pack is only marginally heavier than the outgoing lithium design, yet energy density per kilogram climbs by more than 60 %. That means greater range without a bloated curb weight. Tesla’s multi-chemistry battery management system (BMS) ties it all together, automatically translating voltage, heat, and charge-state nuances to the existing drivetrain. Over-the-air updates allow the BMS to adapt to future cell chemistries, so today’s aluminum ion battery could coexist with tomorrow’s solid-state experiments. Those forward-compatible specs explain why analysts are calling the Tesla battery upgrade one of the most important breakthroughs in modern EV engineering.

Seamless Tesla Retrofit: How Owners Get 1,000 Miles Overnight

Compatibility isn’t a happy accident; it’s the product of years of platform unification across Fremont, Austin, and Shanghai gigafactories. Tesla standardized battery mounts, cooling hookups, and high-voltage connectors under a single architecture called the Cross-Platform Module Interface (CPMI). During a Tesla retrofit appointment, technicians unbolt the old pack, slide in the aluminum ion replacement, connect the CPMI harness, and perform a software handshake—all in about 90 minutes. No chassis cutting, no rewiring, no re-certification required. A quick firmware push over LTE equips the car’s brain to recognize the higher-voltage chemistry. Once complete, owners pull out of the bay with triple the range and access to 5 minute EV charging at V4 and V5 Superchargers. The Tesla battery upgrade therefore resembles a smartphone OS update more than a traditional mechanical overhaul. It keeps customers locked into Tesla’s digital ecosystem, where revenue streams flow from Full Self-Driving subscriptions, premium connectivity, and in-app energy services. Economically, the value proposition is unbeatable: $5,000 versus the $30,000–$60,000 price tag of a new vehicle. For a deeper dive into Tesla service logistics, check out our guide to Mobile Service Ranger diagnostics—another example of how modular design is redefining convenience. Below this section, we embed the full YouTube breakdown (ID: AayNYrCedb0) so you can see the retrofit in action.

From Planned Obsolescence to Perpetual Platforms

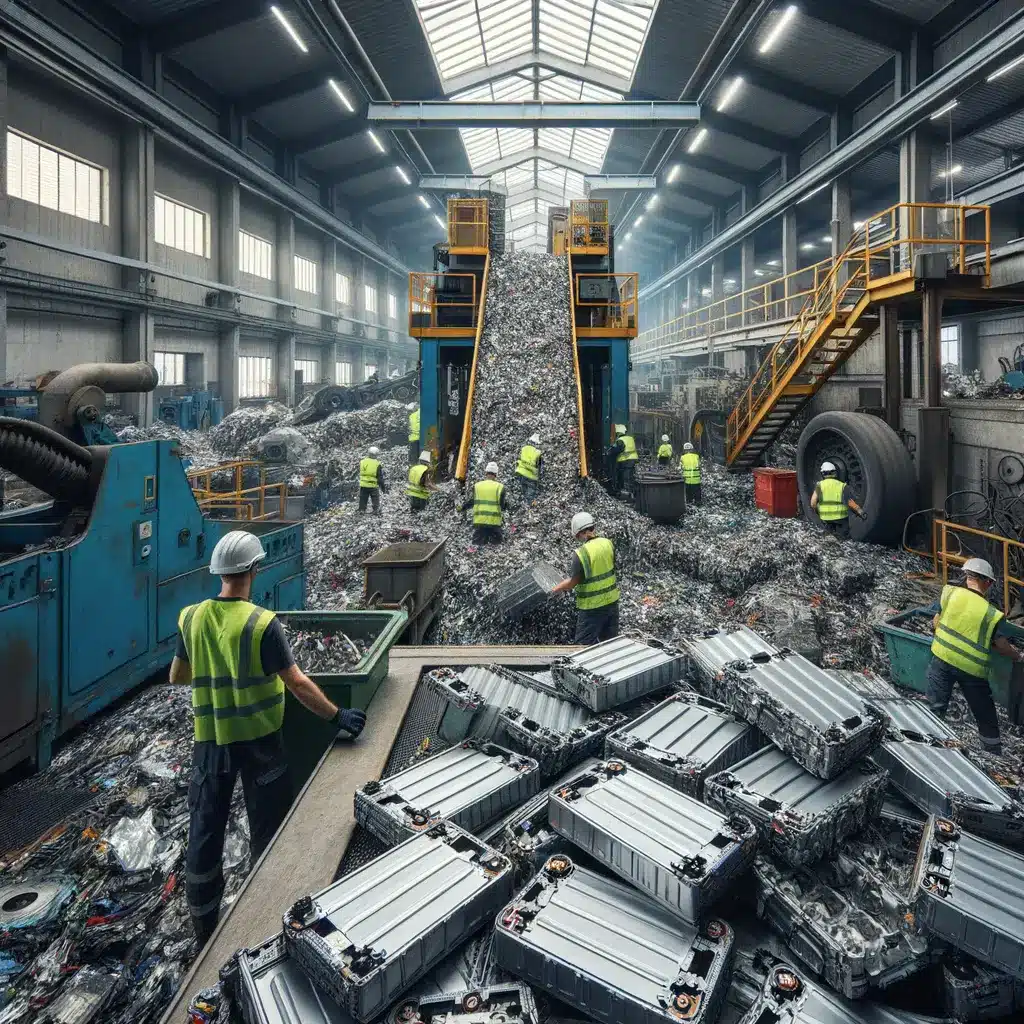

Detroit’s century-old business model hinges on selling next year’s model to replace last year’s ‘outdated’ one. Tesla’s aluminum ion strategy demolishes that cycle by treating cars like upgradable smartphones. With each Tesla battery upgrade, the resale value of existing vehicles rises, eroding the psychological need for a brand-new purchase. This shift forces legacy manufacturers to rethink revenue. Will they chase razor-thin margins on hardware, or pivot to software services and circular-economy parts? Early signals suggest a scramble: Volkswagen is trialing subscription-based performance boosts, and GM announced modular Ultifi architecture—clear echoes of Tesla’s playbook. Environmental impact is equally profound. Extending a vehicle’s lifespan by even five years avoids the carbon emissions embedded in mining, refining, and assembling a replacement chassis. Aluminum ion’s recyclability strengthens the loop: end-of-life packs can be melted down and reborn as new electrodes, virtually eliminating hazardous waste common to cobalt-rich chemistries. Analysts at BloombergNEF estimate that widespread retrofits could cut global battery-production emissions by up to 30 % by 2035. For readers interested in sustainability metrics, revisit our article on life-cycle analysis of EV manufacturing. In short, Tesla’s pivot from disposable products to perpetual platforms rewires both consumer expectations and industrial supply chains, and it does so while keeping the primary keyword—Tesla battery upgrade—squarely at the heart of the narrative.

Grid, Home, and Ecosystem: Beyond the Driveway

A 1,000 mile range battery that fills in five minutes raises an obvious question: can the grid handle the surge? Tesla’s answer is a sophisticated blend of hardware and software. Every new V4 and V5 Supercharger pairs with a Megapack that charges during off-peak hours and discharges when drivers plug in, flattening demand spikes. On the residential side, the Tesla app already schedules home charging for 2 – 5 a.m., when kilowatt rates are cheapest. Here’s where things get interesting: the aluminum ion battery stores so much energy that vehicle-to-grid (V2G) capability becomes genuinely valuable. Pilot programs in California show parked cars exporting surplus electricity back to the neighborhood, effectively acting as rolling power banks. Imagine offsetting your utility bill—or keeping the lights on during a blackout—simply by parking in your garage. The economic model aligns perfectly with Tesla’s ecosystem play: more energy passing through your vehicle means more data, more services, and more subscription revenue. For a primer on how Megapack buffering works, see our explainer on stationary storage economics. By integrating fast charging, V2G, and renewable buffering, the Tesla battery upgrade is less about autonomy on the highway and more about autonomy from the grid—a paradigm that places consumers, not utilities, at the center of the energy landscape.

Future-Proof Mobility: What Comes After the Tesla Battery Upgrade

If history is any guide, today’s breakthrough becomes tomorrow’s baseline. The Tesla battery upgrade demonstrates how modular hardware, over-the-air firmware, and service-centric revenue converge to future-proof mobility. Expect several ripple effects. First, insurance models will evolve to factor in continuously improving safety and range—check our recent piece on telematics-based EV insurance. Second, secondary markets will flourish; a 2022 Model 3 with an aluminum ion pack could outperform brand-new competitors, compressing depreciation curves industry-wide. Third, research into next-gen chemistries such as solid-state or sodium-ion will accelerate, because Tesla has proven that retrofitting is commercially viable. When a superior chemistry emerges, the same CPMI interface can welcome it with minimal mechanical changes. Finally, consumer expectations now include the right to upgrade rather than replace—a cultural shift akin to the smartphone era. By anchoring its strategy on the Tesla battery upgrade, the company is simultaneously reducing waste, securing customer loyalty, and erecting formidable barriers to entry. Whether you view the move as altruistic sustainability or brilliant market control, one conclusion is clear: the days of throwing away perfectly good cars are numbered. Buckle up; the next software notification on your dashboard might unlock another quantum leap in capability, and you won’t need a new VIN to get it.